As an employee, safety is your top priority. That’s why it’s so important to know the basics of lockout/Tagout procedures – and how to perform them properly. Tagout sample lockout sequence is a set of steps you should go through every time you isolate a hazardous area or device.

Tagout sample lockout sequence is one of the most important procedures in your safety protocol. You must have a Tagout sample sequence in place so that workers know the safety procedures you must follow when working with dangerous equipment. Knowing a few tips on creating a Tagout sample sequence will help you ensure everyone understands it.

What Is A Lockout/Tagout?

A lockout/Tagout is a procedure to prevent workers from entering or leaving a hazardous area while the site is still operating. This is essential, especially when there are any potential hazards present. Tagout is a safety procedure we use in the workplace to prevent injuries.

They involve stopping work activity and ensuring all workers are safely out of the area before restarting. You should perform Tagout at every change in the task. Such as when someone moves from one area to another within the plant or facility. Following these simple guidelines can ensure safe working conditions for everyone involved.

10 Key Steps For Tagout Sample Lockout Sequence

Tagout sample lockout sequence is an important safety procedure you should carry out in an emergency. Ensure well-versing all workers in the Tagout sample lockout sequence so they can immediately start the procedure in the event of a spill.

Always use gloves and eye protection when working with hazardous materials, and ensure the correct equipment is readily available. Be quick in completing the Tagout sample lockout sequence to minimize exposure time for workers.

1.Identify The Procedure To Use

You must follow a few procedural steps when using any new process – making sure it is safe first and foremost. After confirming the procedure’s safety, ensure to brief all personnel on what they need t do and how it will work. Finally, test the process for accuracy and consistency before implementing it widely.

2.Prepare For The Shutdown.

In the event of a shutdown, you must follow the Tagout sample lockout sequence to avoid accidents or injuries. By following this procedure correctly, everyone will be safe, and you can maintain productivity during the blackout.

Ensure all personnel is familiar with the ten steps of the Tagout sample lockout sequence so that transitioning into a shutdown goes as smoothly as possible. Properly executing it will help prevent any potential problems from arising.

3.Notify All Affected Employees

You must follow a Tagout sample lockout sequence to prevent potential safety hazards. This will ensure notifying all employees of the finished work and understanding why it is necessary. Keeping them updated on the progress of the work is essential so they know what to expect and whether or not there are any changes in the plan.

It’s also important to ensure safety remains high on your agenda at all times. Try to find the least disruptive way to do the work while ensuring taking safety precautions.

4.Shut Down The Equipment

Tagout is a critical process that ensures the safe operation of equipment. It’s also one of the most important steps in preventing accidents. The purpose of Tagout is to disconnect operators from equipment so that they can’t accidentally start it up or cause any damage.

This usually happens during maintenance tasks. When they install new parts, or when you eed totake apart the equipment for repairs. Safely shutting down equipment is a crucial step in preventing accidents. Here are some tips on how to do it:

- Ensure all personnel is clear from the work area. And you left no equipment running behind.

- Shut down the power to the system by turning off switches, plugs, or breakers as necessary. Verify closing all circuit breakers. And disconnecting any cables from their sockets which you don’t need. Make sure you tag them out accordingly.

- Verify no gas or oil is flowing to any of the machinery- if there is, turn off the main fuel line leading into each piece of machinery using an appropriate valve(s).

4 Tag out all circuit breakers and disconnect any cables not needed before finally closing valves on each machine in turn– this will ensure shutting down everything properly and without causing damage (and doing your job a lot easier later!). Record your findings in a Tagout log so you can track what’s happened while working on-site.

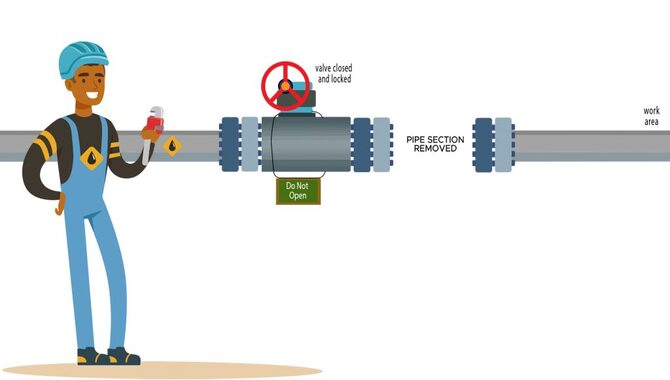

5.Isolate The Equipment

Tagout is one of the most important safety procedures you can follow when working with hazardous chemicals. It’s especially important when working with hazardous chemicals, as they can cause serious health and safety hazards if not properly handled. Whenever working on hazardous (or any type of) equipment, it is important to isolate the device as quickly and safely as possible. You should always complete this sequence in a step-by-step manner:

- Turn off all power sources and disconnect all cables.

- Make sure nobody enters the work area until all safety procedures are complete -Tagout checklist included.

- Perform the Tagout procedure by performing the following tasks: lockout, disable device functions, clear security codes/passwords if necessary, and shutdown.

4 Ensure everyone knows how to perform each task in an emergency.

6.Add The Individual Locks.

When working in sensitive areas, keeping a Tagout sample lockout sequence in mind is always important. This will ensure that you and your team remain safe while completing tasks.

It’s also essential to use the right tools for the job – Tagout Sampler, Latch Key, Wrench etcetera. And finally, make sure you are familiar with the Tagout sample lockout sequence so you can avoid any mishaps or accidents in future jobs.

7.Check Stored Energy

Stored energy is a major concern for employers looking to protect their employees from accidents. By implementing a Tagout sample lockout sequence, you can help ensure that your employees are safe and compliant with OSHA guidelines. A Tagout sample lockout sequence is a set of procedures workers must follow when exiting hazardous areas.

It includes checking to ensure to discharge of any stored energy and putting away all tools and equipment properly. And ensure to secure any loose wires. Following a Tagout sample lockout sequence can help protect your employees from potential accidents and injuries.

8.Verify The Isolation Of The Machine Or Equipment

It is important to verify the machine’s or equipment’s isolation before starting any work. By following a lockout sequence correctly, you can avoid any safety risks. Ensure that the machine or equipment is isolated from other machines and sources of power and that all workers know the correct procedure. Remember to always use a Tagout checklist when conducting a lockout sequence.

9.Shut Off Controls

When it comes to safety, there is no room for error. To ensure the safety of workers and prevent accidents, it is crucial to shut off any valves, switches, or manifolds that could be in the way. Supervisors should get tagged out when working on hazardous equipment so they are aware of what’s happening at all times.

Lastly, ensure you have a written Tagout procedure in place so everyone knows what has been done exactly and who was responsible for each step. This will help reduce workplace accidents and casualties in the future.

10.Return Equipment To Service

Returning equipment to service is important in ensuring that it remains safe and operable. Not only will it help prevent accidents, but it will also keep the equipment in top condition so you can use it to its full potential. Here are a few tips for returning equipment to service:

– Follow the correct lockout sequence for the machine you’re returning. This will ensure that the machinery is safe and prevents anyone from accidentally operating it while servicing.

– Keep records of all work done on the machine, including any modifications or repairs. This will help you remember how everything was when you returned it to service and document any problems that it may have caused.

– Ensure all necessary safety devices are operational before returning equipment to service. This includes things like guardrails and emergency stop buttons.

Importance Of Lockout/Tagout Procedures

Tagout is a safety procedure ensuring shutting down equipment properly to prevent injuries. By following lockout/Tagout procedures, you can help protect yourself and others from possible accidents.

People should always follow Tagout procedures when working with dangerous machinery or tools, including during startup, shutdown, maintenance, and repairs.

Lockout/Tagout procedures are important for the safety of workers and the public. By following a standardized sequence, you can ensure that all employees are safe and that any potential contamination is absent quickly and effectively.

Conclusion

The Tagout sample lockout sequence is an essential safety procedure that protects workers and equipment from hazardous energy. It is a good practice to implement lockout/Tagout procedures for equipment that is used in tandem with potentially dangerous systems.

The procedure ensures the user has enough time to react in case a hazardous situation arises.In addition to the methods mentioned above, it’s also important to train your staff and explain the importance of Tagout procedures. Sometimes, people need to remember these simple steps even after years of experience, which can lead to serious accidents.

So, make sure everyone follows this guidance and always be alert while working around such equipment. The ten key steps listed in this blog will help you ensure that your target sample lockout sequence is effective and safe. Make sure to follow these steps to ensure a successful and safe Tagout sample lockout sequence.

Frequently Asked Questions

1.When Preparing For Lockout/Tagout, You Should?

Ans: It is important to remember the lockout/Tagout procedure before working on any machinery or equipment. This ensures that everyone is aware of the steps and procedures and that no one is harmed.

Once you have determined that all personnel have been cleared from the work area, you should isolate all energy sources by locking out/tagging each one.

It would be best if you also verified that the equipment is isolated and safe. After verifying that the equipment is safe, you should begin work by checking for any stored energy in the system. This can help you determine if fires or electric shocks are dangerous.

2.What Is A Tagout Sample Lockout Sequence?

Ans: A Tagout sample lockout sequence is a step-by-step guide to isolate equipment energy sources safely. It should include the necessary steps to secure the equipment and prevent unauthorized access.

All personnel involved in the equipment lockout process need training and knowledge of the Tagout sample lockout sequence. The Tagout sample lockout sequence needs to be reviewed and approved by a qualified person before implementing it.

3.Why Should I Have A Tagout Sample Lockout Sequence?

Ans: A Tagout sample lockout sequence can help ensure that machines are properly shut down and locked out before maintenance. This helps prevent accidents or injury by ensuring personnel does not access the machine while finishing work on it. Additionally, it provides a written record of who was responsible for the lockout and when they completed it.

4.How Does The Tagout Sample Lockout Sequence Help Me?

Ans: The Tagout sample lockout sequence is a safety process that ensures hazardous energy sources are isolated and locked out before maintenance or repair work is begun.

This helps to protect workers from the potential dangers of exposed energy sources and reduces the risk of injury or death in the workplace. Following the Tagout, sample lockout sequence can help reduce the risk of injury or death due to accidental exposure to hazardous energy sources.

5.How Do I Start Creating My Own Tagout Sample Lockout Sequence?

Ans: To start creating your own Tagout sample lockout sequence, you will first have to identify the type of equipment or process you will be locking out. Once you have done this, determine what energy sources need to be controlled.

Next, develop a written procedure outlining the steps necessary for safely controlling energy sources. Lastly, establish Tagout devices and make sure they are correctly placed and functioning properly.

Leave a Reply